|

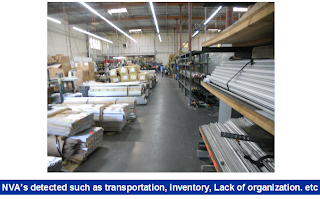

| a kaizen event of 4 days started with a lean overview and 5'S training, then we visited the area and made an assessment, and rate the 5'sStatus. |

Then we set a series of Objectives of the kaizen event, this was previously discussed with the management team and then during the training to the entire kaizen team.

And started to work on the area, we divided the tasks so it was easier to clear the area, sort the materials and equipment, clean the area and the equipment, as well as start cleaning and organizing the materials,

Materials on the floor were placed on racks and properly identified.

After a material usage analysis, we found out that the team was requesting too much material, so we decided to delay some orders, because that action did not represented any extra fee from supplier, du to the fact that the material was std.

Continued cleaning and disposing no longer in use materials and old fixtures from the area.

Removed material from the floor and placed on racks for proper ID and storage.

An ergonomic assessment was made and found that with the proposed material elevator, the back injuries would be eliminated

Spaguetti diagram to understand the travel distance of the materials before and after relayout of the area. This Task would be schedule once the new equipment arrived to the plant and was assigned to the machine shop manager.

A table of results was presented to the team after the Kaizen Event, a special meal was offerd by the operations manager to the team in return of the great teamwork effort made.

A table of results was presented to the team after the Kaizen Event, a special meal was offerd by the operations manager to the team in return of the great teamwork effort made.

This was the result of the 4 day kaizen event, aisle lines were marked never before made.

This is the receiving area cleared after the event.

I must say that the operations team was amazed of the changed achieve that week, because most of them were very reluctant that a change like this would be almost impossible. I'm very happy because we demonstrated that with management support, the proper training techniques and the hard work of all team members, everything is possible. The people's minds were positively changed that week and I'm pretty sure they would continuing improving their company for good.

No hay comentarios:

Publicar un comentario